Pharma Solutions

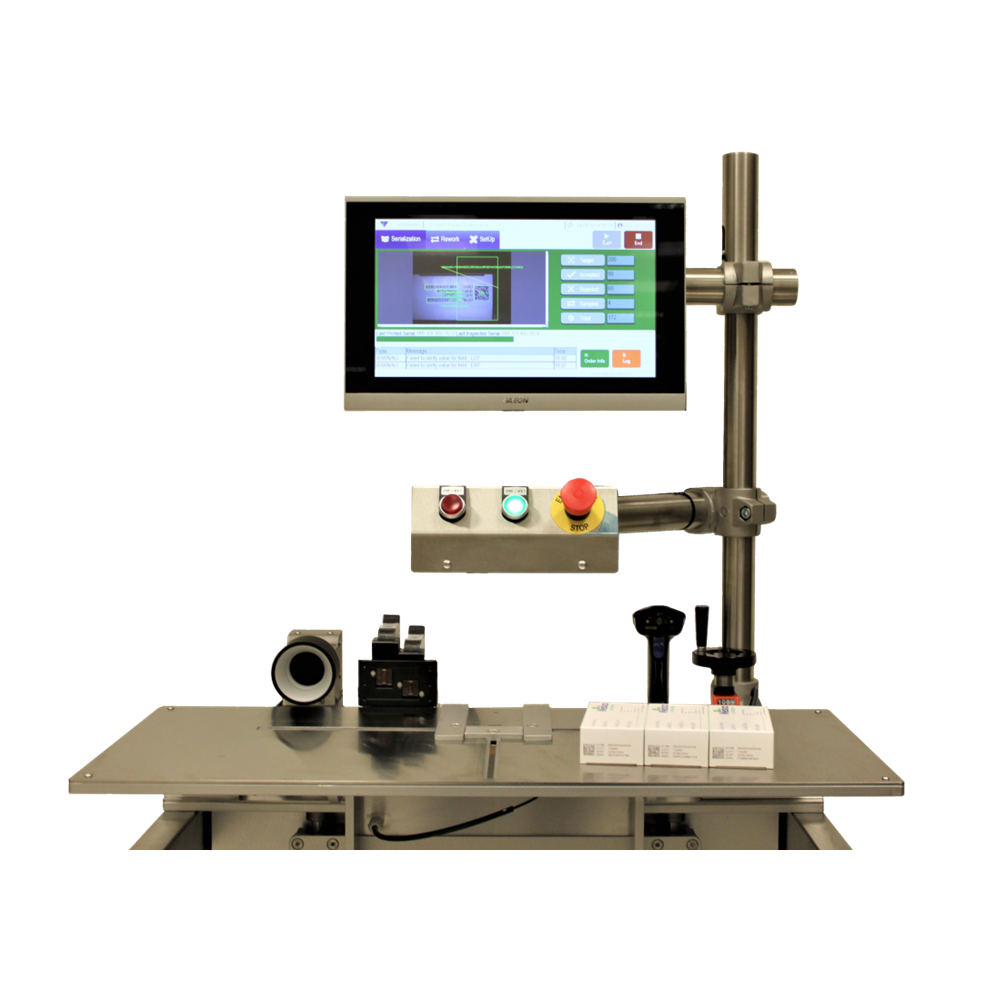

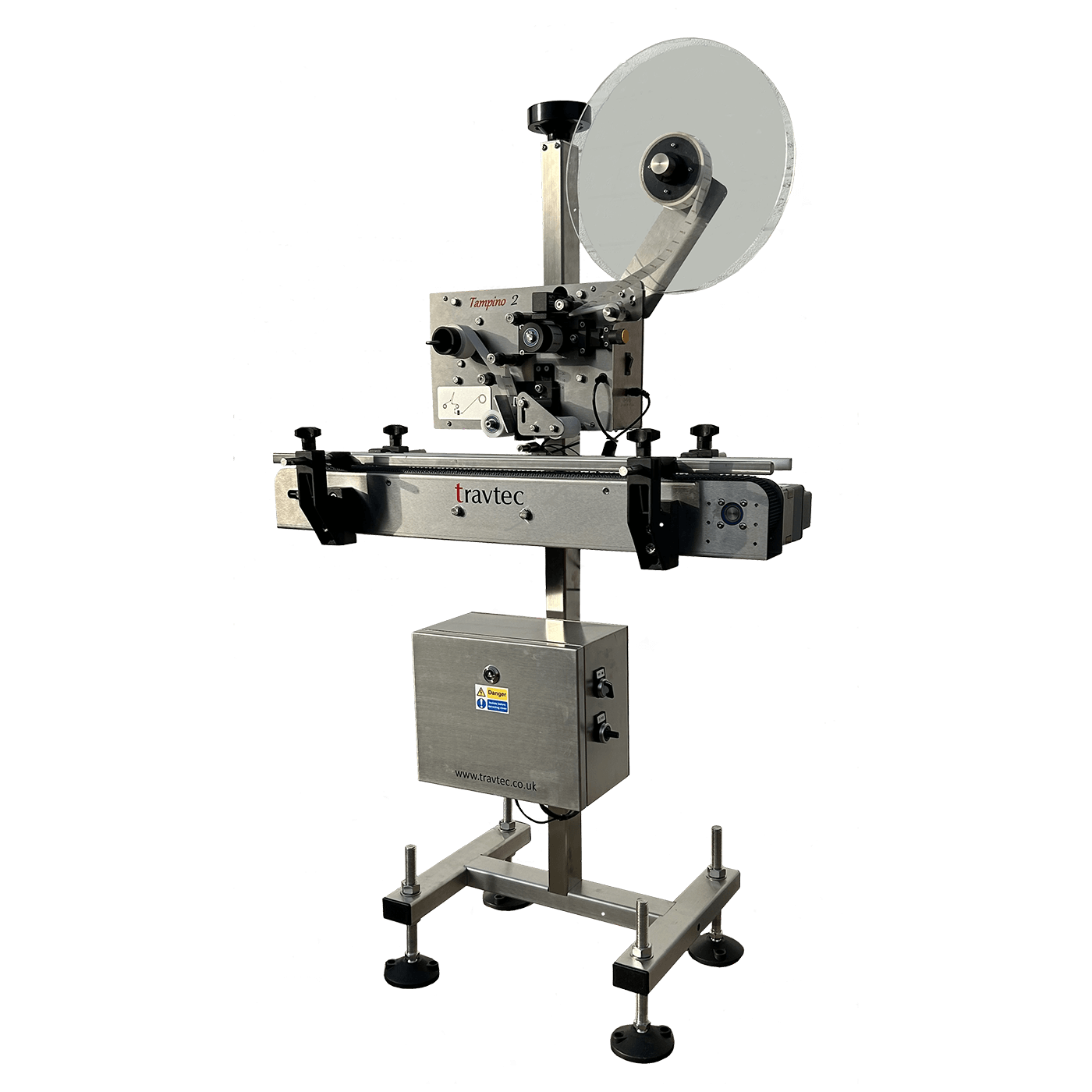

The Travtec Group has over 30 years experience in supporting the pharmaceutical industry. Our machines are used all over the world and our customers come back to us time and again. We have a range of standard machines offering you the ultimate answer to your problem and we believe this makes us a leader in our field.

Watch the video

We have supplied many bespoke machines to the pharma industry and installed them across the globe. See an example of the technical skills of the team. We are ready and waiting to meet your specialist handling requirements.

Operating as a full partnership with our customers, from initial consultation through to development, installation and commissioning we ensure a fit for purpose turn-key solution for all your product handling needs

Sunala Limited

Unit 17,

Meadowcroft Way,

Leigh Business Park,

Leigh, Lancashire,

WN7 3XZ

2024 All Rights Reserved Sunala Limited